Go Beyond Manage

Your Factory. Auto-Improve It.

ProManage MES/MOM

Trusted by manufacturers worldwide

Built for productiondecision-makers

You have production data.

Now turn it into continuous improvement.

One platform.Multiple capabilities.

Production Visibility

Real-time dashboards showing OEE, downtime, production status, and performance trends across all lines.

Performance Reporting

Automated reports with KPIs, shift summaries, and historical analysis for continuous improvement.

Workflow & Governance

Digital workflows for shift handoffs, quality checks, and process compliance documentation.

Proven Roadmap for your Success inManufacturing

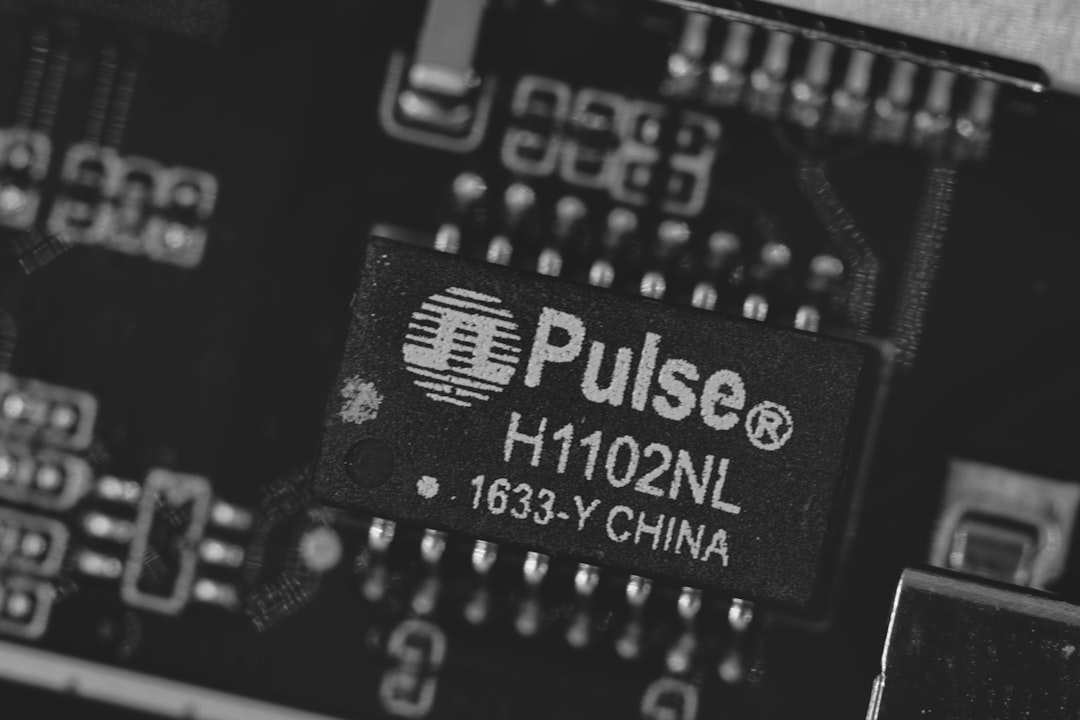

Enhanced IoT deployment & Real-time data collection

Share the status with Plant & Operators

Analyze the losses and root causes using different tools

Start Kaizens to eliminate the root causes of losses.

Integrations with ERP to manage work flows

Become Smart Factory with ProManageMES/MOM

Web Based

This cloud-based Manufacturing Execution System (MES) allows you to double your production speed by transforming into a smart factory.

AI Power

This cutting-edge Manufacturing Execution System (MES) leverages artificial intelligence to optimize your production processes and boost overall efficiency.

Access anywhere

This cloud-based Manufacturing Execution System (MES) allows you to access your production data from anywhere.

Boost Your Productivity with ProManageWhat Can You Do with ProManage?

Software & Modules

Hardwares

Training & Counsultancy

After Sales Supports

Proven in real production enviroments

Sarah Chen

“I've recommended this website to all of my friends and family and they've all had the same positive experience.”

ProManageTrusted Brands

See ProManage in action

CompanyNews

VİEW ALL NEWS

Doruk Brings ProManage Users Together at the 7th Doruk Gathering Event

Exhibition: Industry 4.0 Applications and Smart Factory Solutions Summit

From the ProManage Blog

A Look at the Heart of the Digital Transformation Journey from Pakten: The 12th Man of Industry Digitalization

Flormar’s Digital Transformation Journey: A New Era in Efficiency, Transparency, and Customer Satisfaction

Frequently Asked Questions

ProManage may be implemented to all companies that work with discrete manufacturing and batch manufacturing processes.

Ready to transform your

manufacturing operations?

Get in touch with our team to schedule a demo and discover how ProManage can help improve your production processes.

+1 (555) 123-4567

Mon-Fri 9am-6pm EST

info@promanage.com

We’ll respond within 24 hours

Global Headquarters

123 Manufacturing Ave, Suite 500